Three-dimensional printing is one of the many wonders of modern technology. It's the first step towards real life Star Trek replicators and Timeline-esque teleportation chambers. While we aren't at the level of reconstructing strands of DNA, it's already possible to make tons of fun and useful designs on a 3D printer.

Some of the most interesting 3D prints of late are what Minecraft players dream up in-game. Their blocky contraptions can be perfectly realized through a 3D-printed sculpture. And if you're playing on the WonderHowTo server, you have a chance to see your build in physicality, because the Minecraft World is giving away a free 3D print to one lucky Minecraft architect.

Photo by postapocalyptic

Photo by postapocalyptic

To get your creative juices flowing, I thought I would explain how a 3D printer works and what you can expect from the final print object.

What Am I Printing?

There are all kinds of materials used in 3D printing; wax, chocolate, resin, ceramic, and nylon, but the most common is ABS plastic. ABS is a sturdy thermoplastic perfect for small nuts, bolts, action figures, robot parts, and a million other things. If you're ordering a 3D print from a company or buying your own 3D printer, chances are you'll be using ABS filament to create your models.

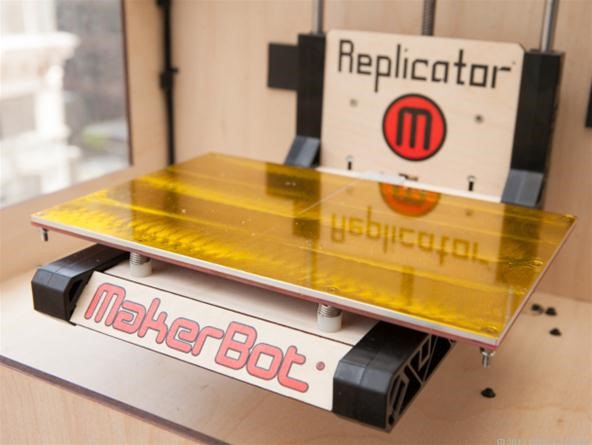

Filaments come in all different colors, but most hobby printers can only print one color filament at a time. If you want a multi-colored object, you can always design two halves that snap together forming a whole object. The Makerbot Replicator is the only exception, as it can print a maximum of two colors simultaneously. If you are ordering from a professional 3D printing service, you will likely be able to have multiple colors in your design file.

How Does the Plastic Turn into My Design?

The plastic filament of ABS is fed through a heating mechanism and nozzle in the printer. The extrusion temperature of ABS plastic is around 200 degrees Celsius. As the plastic melts, it is forced through the nozzle and comes out in a fine liquid strand.

To form this strand into an object, the printer moves a platform in three dimensions. Starting at the bottom, the nozzle traces the outline of the model and fills in the middle with a crisscross pattern of plastic strands. As they cool, the strands melt together forming a strong solid body.

Where Can I Get My Own?

The last few years have seen an explosion in 3D printing startups. A quick Google search will give you a plethora of available options for for-sale 3D printers, but my favorite is the Replicator. One of the earliest and most recognized brands of 3D printers is Makerbot. And one of the cheapest ones is the Solidoodle.

Photo by CNET

Photo by CNET

They offer a fairly large print area, two-color printing, and a convenient LCD user interface. The Replicator is currently going for $1,750 US. If you have the money and plan on using your printer for a while, go with this one. Also, If you have the money for this printer, buy an extra and be sure to send it to me.

Most printers will come as a kit or as a finished product. You can save money by buying essential parts and improvising the rest.

But I Can't Design 3D Models!

No problem. Thingaverse is a great site that is basically a free 3D model library. You can find the design and print files for whatever you need on there. If you are keen on the Minecraft prints, you don't even need to make a file, as the printer will convert the files for you. Essentially, you just used Minecraft as a 3D modeling program!

If you're big into three-dimensional Minecraft prints, then using Mineways to make your 3D models and the Shapeways service to print them might be the way to go, instead of buying your own 3D printer. There are plenty of other 3D printing services out there, too.

If you have a totally original idea for a print, or you just want to try 3D modeling for yourself, I suggest starting out slow with SketchUp, then building up to CAD programs.

How Strong Is the Plastic?

Generally speaking, ABS plastic is very strong. However, it all depends on the dimensions of your 3D print. A thin object will break more easily than a thicker one. If you are making a decorative sculpture of, say, the Eiffel Tower, you don't need to worry about the legs supporting the weight.

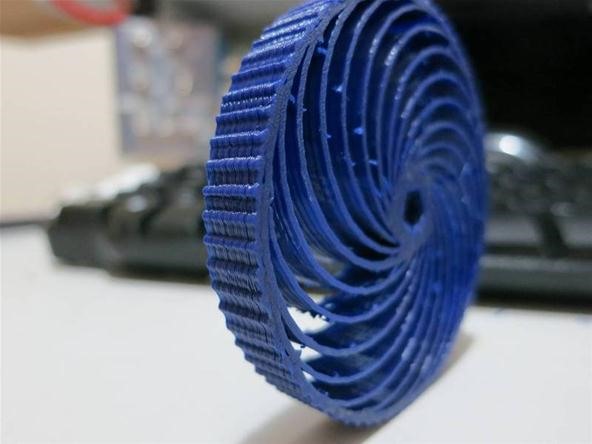

If you are clever, you can even print flexible plastic pieces.

Photo by tjhowse

Photo by tjhowse

Now that you know the basics of 3D printing, it's time to design the coolest Minecraft model ever and win that prize! Here are a few epic Minecraft prints to help inspire. You can see more here.

Photo by PCWorld

Photo by PCWorld

Photo by Geeky Gadgets

Photo by Geeky Gadgets

What would you design in Minecraft? I would like to see some Minecraft water fountains with space for aquarium tubing!

Main photo by Quinn Norton

Just updated your iPhone? You'll find new emoji, enhanced security, podcast transcripts, Apple Cash virtual numbers, and other useful features. There are even new additions hidden within Safari. Find out what's new and changed on your iPhone with the iOS 17.4 update.

6 Comments

Where could i get a design for one and build my own

You can find everything you need to build your own at www.reprap.org This site is great for providing DIY 3d printer designes and kits. I am building one right now. I will upload a video when I am done. I am also thinking about a way people can tell me what they want and I will design it for them, print it, and send it to them. I can't do it for free, but I will be doing it for cheep when I am up and running at the end of the summer.

Are you printing out your RepRap? I love that about RepRaps... self-replication. Though it would be cooler if they were totally self-replicating :)

Super cool Jeremy!

Nope. I don't have the printer yet. But soon. I have all of the motors and most of the other electronics and components to start laying out my boards. I am on a strict budget. I am having to design and machine most of the parts myself. I am a machinist fabricator so I am fortunate enough to do most of it for little to no cost. I am building a foundry to mold the pieces I don't want to machine. I will post pictures and a video of the whole project from start to finish. It should be done in several weeks.

Sweet. Can't wait to see the outcome!

Share Your Thoughts